Compounding personnel are sufficiently proficient, educated, instructed, and educated to correctly perform and doc the subsequent activities of their sterile compounding duties: Conduct antiseptic hand cleansing and disinfection of nonsterile compounding surfaces; Select and correctly don protecting gloves, goggles, gowns, masks, and hair and shoe covers; Use laminar movement clean-air hoods, barrier isolators, along with other contamination Command products that happen to be appropriate for the danger stage; Detect, weigh, and measure components; and Manipulate sterile goods aseptically, sterilize large-possibility amount CSPs, and label and high-quality inspect CSPs. Substances have their suitable id, top quality, and purity. Opened or partially applied offers of ingredients for subsequent use in CSPs are properly stored beneath limited accessibility situations while in the compounding facility. This sort of packages can not be applied when visual inspection detects unauthorized breaks from the container, closure, and seal; when the contents do not possess the expected look, aroma, and texture; if the contents do not move identification tests specified with the compounding facility; and when either the past-use or expiration day has become exceeded. To attenuate the generation of bacterial endotoxins, drinking water-containing CSPs that are nonsterile all through any phase of the compounding treatment are sterilized within six hours just after finishing the preparing.

Throughout incubation, if any device found to get harmed needs to be recorded in media fill observation structure.

Each individual media filled device needs to be examined by qualified Microbiologist right after 3rd working day, 7th working day, 10th working day and 14th day.

I've heard about double-strength media. Does that let me to implement water to dilute it since it's double-toughness?

All cartoned provides are decontaminated while in the anteroom region by getting rid of them from shipping and delivery cartons and wiping or spraying using a disinfecting agent, such as sterile IPA, though currently being transferred into a clean, sanitized cart or other conveyance for introduction in the buffer or cleanse location.

These danger concentrations utilize to the caliber of CSPs immediately once the ultimate aseptic mixing or filling or immediately after the closing sterilization, Except if precluded by the specific features on the planning, which include lipid-centered emulsions wherever administration should be accomplished within just 12 several hours of planning. Upon subsequent storage and shipping and delivery of freshly completed CSPs, a rise in the hazards of chemical degradation of substances, contamination from Bodily harm to packaging, and permeability of plastic and elastomeric packaging is expected.

Bulk, or unformulated, drug substances and included substances, or excipients, must be stored in tightly closed containers beneath temperature, humidity, and lighting conditions that happen to be either indicated in official monographs or approved by suppliers; also the day of receipt while in the compounding facility must be clearly and indelibly marked on Just about every package of ingredient.

NONSTERILE INGREDIENTS click here and Factors If any nonsterile parts, like containers, gadgets, and components are used to come up with a CSP, these types of CSPs need to be compounded at a higher-risk stage. Nonsterile Energetic ingredients and extra substances, or excipients, for CSPs need to if possible be official USP or NF content articles. When nonofficial ingredients are made use of, they need to be accompanied by certificates of study from their suppliers to aid compounding personnel in judging the more info id, top quality, and purity in relation to the intended use in a certain CSP.

At the conclusion of cleaning, collect very last rinses sample from sampling level and send out to QC department with prepared data for testing of prior merchandise traces.

The size from the crucial site influences the chance of contamination entering the product: the bigger the uncovered area, the greater the risk. An open vial or bottle exposes to contamination a crucial site of much larger location than the tip of a 26-gauge needle.

On top of that, the new era of freeze and thaw containers Celsius FFT/FFTp with Safecore Technologies can be found in some normal configurations tested by SIT. The test is validated to detect defects as compact as 2 µm and it is done in-line on 100% in the SUS all through manufacturing to make sure the absence of microbial ingress and liquid leak within the intented use-situation problems, such as in the course of storage and shipment of liquid or frozen drug substances or drug merchandise.

The EU GMP Guide11 provides much more particulars on this issue: – “Validation of aseptic processing need to include a method simulation test employing a nutrient medium (media fill) … The procedure simulation test ought to imitate as closely as you can the program manufacturing process and include many of the critical subsequent manufacturing steps.“

How we can easily do to detect the residues of TSB advancement medium after cleaning of equipement? acceptable creteria and by wich want approach

for satisfactory tolerances with the weights utilized. Also, precisely the same quantity of Sterile H2o for Injection accustomed to assess volumetric precision is then weighed on the equilibrium employed in conjunction with the ACD. One example is, if forty mL of water was Utilized in the volumetric assessment, its corresponding weight needs to be about 40 g (assuming the relative density of drinking water is 1.

Angus T. Jones Then & Now!

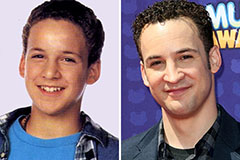

Angus T. Jones Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now!